Lashing Equipments

Submit your Interest

Submit your Interest

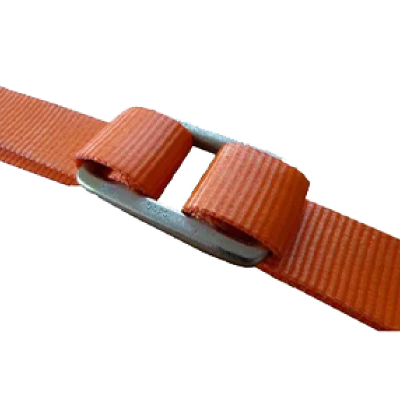

Cargo Lashing Belts & Accessories

Lashing is the process of securing the cargo for transportation with the goal of reducing shifting during transit. Lashing Strap is a device that can be fixed to a lashing point for securing the cargo during transit. A lashing Strap consists of the strap, the ratchet, and hooks. The polyester material is used in the fabrication of Lashing belts and alloy steel is used in the manufacturing of Lashing hooks. These materials allow the Polyester Lashing System to handle up to 10 Tons individually.

Available Brands

Cargo Lashing Chains & Accessories

The Cargo Lashing Chain is applicable for safeguarding heavy loads during transportation. The chain length can be adjusted as per the requirements and can be constricted swiftly with the complementary Turnbuckle. Lashing Chains and associate mechanisms are collectively used to make locking to tie down large industrial loads on low loaders. A sturdier alternative to ratchet straps is Lashing Chains manufactured using alloy Steel. Generally, a combination of Chains with Hooks on the ends and Ratchet Load Binders are placed in between to shorten and apply significant pulling pressure on the chain. This secures the binding of the load to the flatbed truck or lorry.

Available Brands

Cargo Lashing Ropes & Accessories

The Cargo Lashing Wire Ropes and their accessories are suitable for securing heavy loads during transit. The rope length can be adjusted variably and can be tightened quickly using Turnbuckle. Lashing ropes, clamps, and turnbuckles are used in combination to secure assemblies and restrain large industrial loads on ships. A stronger alternative to ratchet straps is the Wire Rope Lashings which are fabricated using High carbon steel for the Wire Ropes, and forged Steel for the clamps, Turnbuckles, and D shackles. There is no restriction on how much weight it can handle as this can be set by increasing the number of Lashing Ropes.

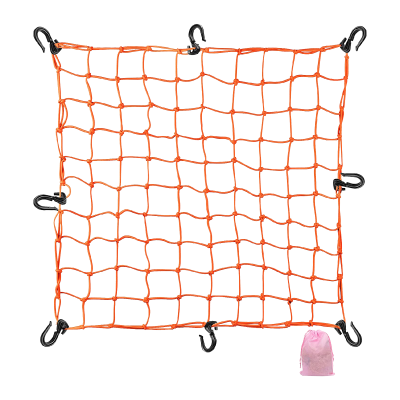

Trailer & Container Lashing System

The Cargo stored in the containers has to be secured on all sides to prevent it from shifting, especially towards the door. The spaces in between the packages and the spaces within the container walls have to be filled. Cargo bars are simpler to use and install. To hold the product in place and stop movement, the bar is either installed between the truck’s sidewalls or from the ground up. Most cargo bars use Steel tubes with rubber feet at the ends of the bar to hold it in place. Cargo bars include a ratchet that holds them in place, allowing the user to adjust the length of the bar easily and secure it tightly. For additional security, a cargo bar can be combined with cargo straps.

Available Brands