Rigging Equipments

Submit your Interest

Submit your Interest

Wire Rope Slings

Wire rope slings are multipurpose and widely used piece of rigging equipment. These slings connect the load to the lifting appliance and are mainly used in applications where strength, durability, and conforming to the shape of the load is a requirement. Wire rope slings are available in a range of configurations for one to choose from, depending on their applications, in different grades mainly 1770 & 1960, in diameters ranging from 8mm to 100mm and capable of handling up to 100 tons. Various components are used in making Wire Rope Slings – Wire Ropes, Aluminium Ferrules, Thimbles, Sockets, etc. Wire rope slings are available from minimum 0.5 mtr and up to any length based on the customers’ requirement.

Available Brands

Polyester Slings

Polyester Slings are perfect for any operations that require meticulous handling. It is primarily used in conditions where minimum stretch is sought after and/or if acid is present, as it is unaffected by common acids and bleaching agents. It is ineffective in places where concentrated sulfuric acid and alkaline are present. Although Polyester Slings don’t provide as much stretch as Nylon, they do provide decent load stability. The other benefits include non-conductivity and resistance to water absorption. Polyester Slings are flexible, and do not take up space, making them easy to use as the operators can easily slide them under a load. They are capable of handling weights upto 100 Tons.

Available Brands

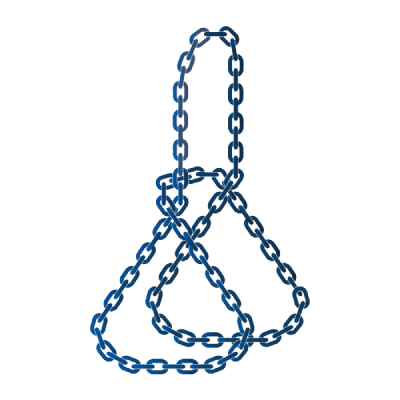

G80 Chain Slings

G80 Chain Slings are used for lifting heavy and enormous loads for regular and repetitive processes. It is the first grade of chain sling approved for overhead lifting. They are used to handle oddly shaped loads at inaccessible positions. Their flexible design provides robustness and longevity as it can endure high impact and exposure to extreme temperature, chemicals and UV rays. You can use chain slings at temperatures above 400°C or below minus 40°C and in acidic environments. G80 Slings has the added benefit of conforming to the shape of the loads. G80 Chain Slings have exceptional strength, anti-resistance and durability.

Available Brands

G100 Chain Slings

G100 Chain Slings are used for lifting heavy and enormous loads for continuous and repetitive processes. G100 Chain Slings along with shortening grabs are used in a wide range of lifting applications and are ideal for construction, infrastructure, and building industries. They are used to handle oddly shaped loads at inaccessible positions. Their flexible design provides robustness and longevity as it can endure high impact and exposure to extreme temperature, chemicals and UV rays. The G100 Chain Sling has a 25% greater Work Load Limit than the G80 Slings. More importantly, it is cost effective compared to conventional slings that use multiple components.

Available Brands

G80 Sling Components

G80 Chain is used along with other components like chain connectors, Hooks, and other working parts of chain slings. G80 Chain slings are user-friendly because of their multifunction compatibility with these parts for various lifting applications. These components are designed to be high in strength, rugged, versatile, and lightweight, and are apt for heavy lifting applications. They are forged from super alloy steel. They go through vigorous rounds of testing where all the forged parts are 100% individually inspected for cracks under magnaflux process after the heat treatment. It is tested at 2.5 times the workload limit and in addition, the parts are tested for dynamic fatigue at 1.5 times the workload limit for 20K cycles and also

checked for breakage.

Available Brands

G80 Lifting Hooks

The G80 Lifting Hooks are generally used as end terminal fitting of slings. It offers an exceptional strength-to-weight ratio and is available in a variety of sizes that suits almost any application. The G80 Lifting Hooks are forged using Super Alloy Steel. Each and every Hook undergo several rounds of testing which includes the magnaflux crack detection after heat treatment and testing at 2.5 times the Work Load Limit. All the load pins are individually tested as well following the heat treatment. Furthermore, batch samples are conducted and fatigue tested at 1.5 times the Work Load Limit at 20K cycles.

Available Brands

G100 Sling Components

G100 Sling components are used for making multi legged slings. These components are designed to be high in strength, rugged, versatile, and lightweight, and are apt for heavy lifting applications. They are forged from super alloy steel. They go through vigorous rounds of testing where all the forged components are 100% individually inspected for cracks under magnaflux process after the heat treatment. The parts are tested for dynamic fatigue at 1.5 times the workload limit for 20K cycles and also checked for breakage. The G100 Sling components have 25% greater Work Load Limit than the G80 components.

Available Brands

G100 Lifting Hooks

The G100 Lifting Hooks are primarily used as end terminal fitting in Multi Legged Lifting Slings. It is available in a variety of sizes that suits almost any application. The G100 Lifting Hooks are made from high-grade Alloy Steel. Each Hook endures multiple rounds of tests like detection of cracks post heat treatment and is tested at 2.5 times the Work Load Limit. All the load pins are individually tested as well following the heat treatment. Furthermore, batch samples are conducted and stress tested at 1.5 times the Work Load Limit at 20K cycles. The G100 Lifting Hooks are apt for handling individually anything from 1 Ton to up to 26.5 Tons.

Available Brands

Lifting Points

The lifting points are threaded or weldable accessories fastened or welded on the load enabling the user to hook the slings onto it for lifting. The lifting points are forged using Super Alloy Steel. They are individually tested at 2.5 times the Working Load Limit. Lifting points are independently tested for magnaflux cracks after heat treatment. Batch sampling of components for testing for fatigue at 1.5 times the Work Load Limit for 20K Cycles. The Eye Bolts can individually lift up to 20MT

Available Brands

Yoke Yellow Points

The Yoke Yellow Points are highly visible and indicate a safety-first appearance. It is used in a wide variety of industrial lifting applications in various industries such as chemical, oil, coal, food processing, cleanroom and precision instruments. The Yoke Yellow Points are manufactured using high-grade Alloy Steel. Each component endures multiple rounds of tests like detection of magnaflux post heat treatment and is scrutinized at 2.5 times the Work Load Limit. In addition, batch samples are conducted and stress tested at 1.5 times the Work Load Limit at 20K cycles. The Yoke Yellow Points are capable of individually handling up to 35 Tons.

Available Brands

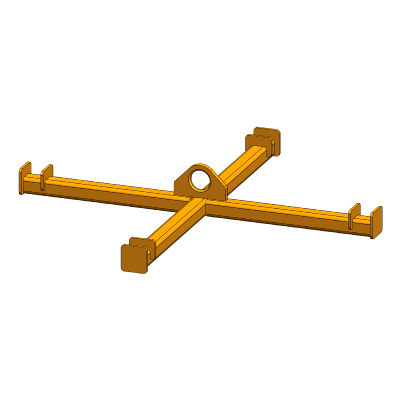

Lifting Beams

If you are facing the challenge of having shorter headroom or lifting wide loads, then a lifting beam is the right option. Lifting beams offer multiple lifting points beneath and can be planned with variable or fixed lifting points. Lifting beams belong to the category of below-the-hook lifting devices that are used to stabilize and support a load during an overhead lift. Spreader beams also belong to this category. Both of these types are used to keep the lifting slings below the device at or perpendicular to the horizon to avoid damage to the load, rigging hardware, and lifting slings. Made with high-quality steel, the lifting beams are capable of handling up to 150 Tons.

Available Brands

Lifting Shackles

Shackles are critical in industries and are typically used to lift, secure, or rig heavy loads like machinery. Usually, it is a U-shaped metal link, which comes with an opening secured by a Screw Pin or Nut, Bolt & Cotter Pin or Round Pin. In all types of rigging systems, particularly in industrial crane rigging, shackles serve as the main connecting link since they make it simple to connect and disconnect various rigging elements. They are made from Carbon & Alloy steel. These shackles are used for lifting moderate to heavy loads in various industries such as manufacturing, construction and shipping. They are capable of lifting up to 150 Tons.

Available Brands

Lifting Clamps

A lifting clamp is a tool used to position, hoist, and transfer materials either horizontally or vertically from one place to another. They are an integral part of almost any industry and are the best choice for transferring, lifting, and moving metal sheets and plates as they leave no marks on the materials. They also make operations easier and safer for operators and construction workers. Lifting clamps in general are fabricated from carbon, and alloy steel and are capable of lifting heavy weights from 1MT to 20MT individually.

Available Brands

Lifting Tongs

Lifting tongs are mostly used to grab objects that are round or cylindrical, including ingots, rolls, tubes, pipes, and many more. In order to adequately sustain the load, the tong arms firmly grasp it below the center. Some Lifters are fitted with contact pads made out of rubber for the safe handling of materials. The clamp automatically grabs and releases the materials using a gravity-controlled locking mechanism. The Scissor Clamp Lifter is used for lifting slabs of marble and granite, headstones, concrete barricades, and median walls. Whatever the type of Lifter is, they are efficient solutions to work faster, better, and with less labor, are reliable with minimal maintenance, and are sturdy and safely constructed using tough steel materials.

Available Brands

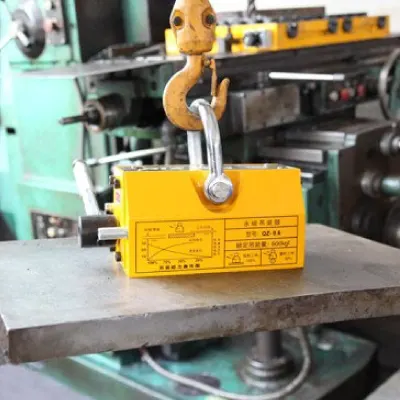

Lifting Tackles

Lifting Tackles include any attachment whether fixed or movable, used to secure the load to lifting appliance. Permanent Magnetic Lifters are mostly utilized during handling operations to lift steel plates, blocks, press molds, etc. as well as load and unload into and out of machinery. Industrial skates are a useful tool for moving machines and other process equipment on flat surfaces, most frequently on factory floors or inside factories. The Crane scale, a powerful scale suspended on a crane hook is used for measuring the weight of loads in numerous industrial applications. Spring Balancer is used to suspend equipment. It can be used in places where flexible positioning of the tool is essential.

Available Brands

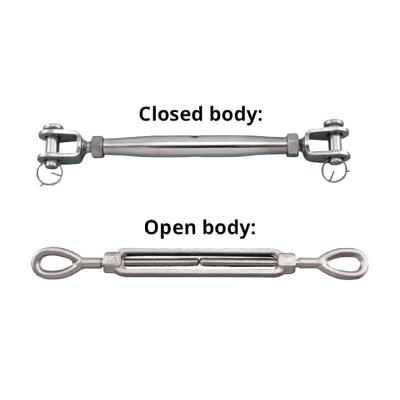

Rigging Accessories

Container Lifting lugs are designed to connect to the top, side, or bottom of a shipping container in order for the container to be hoisted by an overhead crane. Swivels are used for load positioning and swiveling under the load to allow load movement and twisting. Rigging screws are useful in areas where a rope is required to be gripped at a certain tension. Wire Rope Grippers are specifically used for pulling cables and wire ropes wherever it’s required. In places where it is required to lift, pull, or secure loads, then a Wire Rope Puller could be what you need. They are easily transportable and ideal for stowing in work vehicles. These accessories are capable of handling weights up to 15 Tons.

Available Brands